Upload High Res/ Original Artwork

- Vector files preferred in AI or EPS formate.

- High resolution files (300 dpi or more) in JPG, PNG, TIFF, PDF are also accepted.

*NOTE: All designs done with our design tool are NOT FINAL and for visualisation purposes only. A FINAL digital mock up will be sent via email for confirmation BEFORE manufacturing.

Product Information

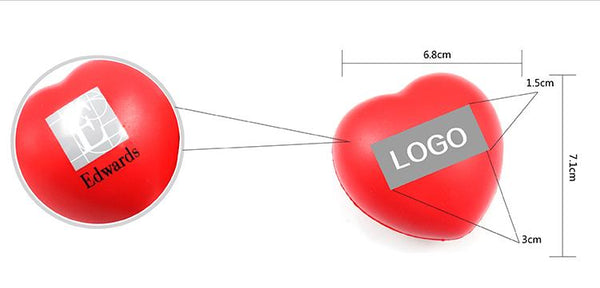

Heart-shaped pu foam stress ball.

SKU: 5101002

Weight: 60g

Dimensions: 7.1x6.8x5.1cm.

Prices quoted are for standard product printing position and size as shown below:

We offer 6 different kind of logo printing processes across our product range. Here is some information on the different processes to help you make a better decision on what to choose.

Screen / Silkscreen Printing

This is one of the most common methods of printing where ink is applied to a

variety of surfaces and products. A stencil or “screen” – hence the name - is

used to define the printed regions by having some areas that allow the ink to

seep through on to the printed surface.

Screen printing is very

durable can be done on a wide variety of materials and surfaces (flat and

curved) hence making it the most popular print method.

Best For: Logos / Images that have 1 to 2 solid colours without

gradients.

Laser Engraving

This is the most economical of all the logo imprint methods and is commonly

used on metallic or wooden products. A high powered laser is used to etch out

an imprint on the surface, and this makes this form of logo imprint extremely

durable.

The colour of the logo is usually a different shade of the

metal’s or wood colour, or possibly removing the top layer of paint on some

products to expose the bare metal beneath, hence creating colour contrast.

Best For: Single-tone logos on wooden and metal products. Low-cost print

customization.

Heat Transfer / Thermal Transfer

This print method is great for a colourful image and logos on porous materials

like fabrics. An image is printed in reverse on a piece of plastic, which is

then placed on the product and transferred over via a heat press. This process

is used because allows for an addition of another base layer of bonding gel or

base behind the ink, which allows the image/logo to adhere better to porous

fabrics and hence have better longevity as opposed to direct printing on the

material.

Best For: Single and full-colour printing, heat resistant surfaces and

fabric products.

Digital Direct Printing

This print method is arguably the most advanced print method where the image

or logo is printed directly on to the product, just like an inkjet does.

However, this high-tech form of printing uses a special type of ink and

process where the ink is immediately bonded to the surface with UV light.

This

process prints directly from an image file in a computer, so no stencil or die

is needed in the process, and can render full-colour images directly on flat

surfaces.

Best For: Full-colour printing on flat, non-porous surfaces and highly

customized products.

Embroidery

This process uses a computer-controlled machine with different coloured

threads sewn prick by prick into a fabric base to create patterns and images.

This also tends to give the logo a “pop-up) or 3D feel as the threads are

stacked together layer upon layer to create the image. This, in turn, makes

the product and logo very wash-resistant and long-wearing.

Best For: Single and multi-colour logos on fabric products like shirts and

bags.

Embossing / Debossing

This process uses a metal die with a protrusion the shape of the desired

imprint/logo, then applying with pressure to a compressible surface. The

result is an indentation in the surface the shape of the imprint/logo on the

metal piece.

Best For: Subtle single tone logos on leather products like notebooks and

key chains.

Delivery FAQ

For most products, we provide a range of delivery options with different lead times and costs. You can choose the desired option in the Delivery Date and Options section on individual product pages.

How are the Estimated Delivery Dates Calculated?

Our estimated delivery dates are calculated from a combination of two factors – the time taken for the printing of the logo/image on the product, and also the time is taken for the air or surface delivery of the product to you.

For eg, if a product takes 3 days for the printing to be completed, and 4 days for air freight, the reflected date will show the total of 7 days from now.

What are the different Shipping Options and Lead Times?

All lead times shown are under normal circumstances and EXCLUDING printing lead time.

Express Air – 2-4 Days

Economy Air – 5-7 Days

Standard (Surface) – 4-5 Weeks

Local fulfilment is available for selected products.

Express Local – 1-2 Working Days

Why are some Shipping Options not available for some products?

Some products contain certain components that make it unsuitable for certain forms of transport.

For eg, electronic products containing lithium-ion batteries above a certain size cannot be shipped by air.

I have a rush order and I need it to be on time. What can I do to ensure that?

The best thing to do is to contact us directly through live chat, email or phone so we can assist you to select the best shipping option to ensure that you receive your products on time.

As the dates are estimated based on standard conditions, a shift of a couple of days might occur due to factors on the side of the air freight and shipping companies, or even customs issues and holidays.

Great Service!

Ordered some door gift for a company DND. Initally, we wanted 1 colour print on the luggage scale however was advise to go for laser engraving on the stainless steel cover.

So glad that we did laser engraving as the logo came out really classy. iwantgift.com even source for a gift box to put the luggage scale. I really appreciate the one stop service

that they provide!

Excellence Service!

The T shirt we printed for our company event was done amazingly. It is not the cheapest option out there but the quality of the full colour print and T shirt is worth the price. After months of wearing, the T shirt didn't shrink or deteriorate. Highly recommended!

GIFT CONCERIGE - TELL US WHAT YOU NEED